| Coad | 667768 | Length | 35.0mm | |

| Type | 1030nm Projection Grating | Width | 20.0mm | |

| Dimension(mm) | 35.0 x 20.0 x 3.0 | Height | 3.0mm | |

| Wavelength(nm) | 1030 | Period | 575nm | |

| Groove Density (l/mm) | 1739.1 | Clear Aperture | 33.0mm x 18.0mm | |

| Diffraction Efficiency (%) | ≥99.0 | Polarization | TE(s-pol) |

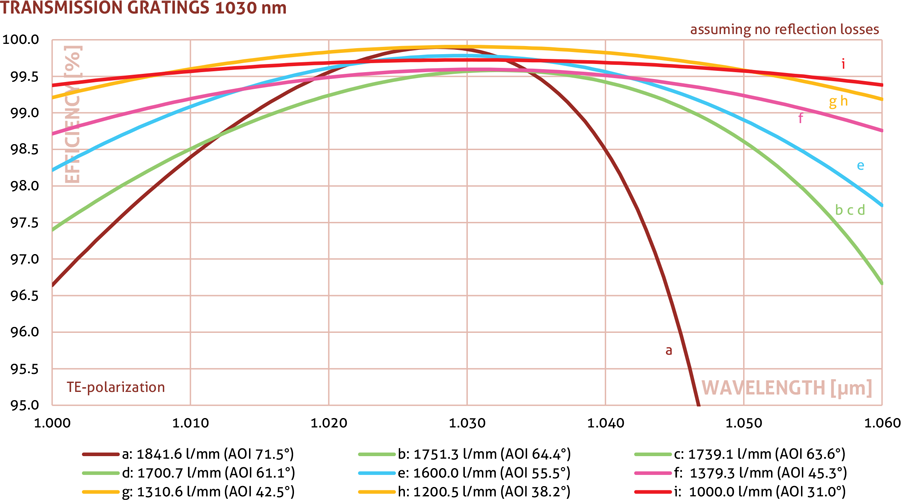

The 1030 nm transmission grating is a high-performance optical component specifically designed for Yb-doped (Yb) laser systems. It is particularly well-suited for applications such as ultrafast lasers, precision machining, and scientific research. Manufactured using specialized optical materials and advanced coating technologies, the grating offers excellent power handling and thermal stability, capable of withstanding kilowatt-level output and MHz repetition rates while maintaining stable optical performance. Its optimized grating structure ensures highly efficient operation around the 1030 nm central wavelength, providing a reliable wavelength control solution for Yb laser systems.。

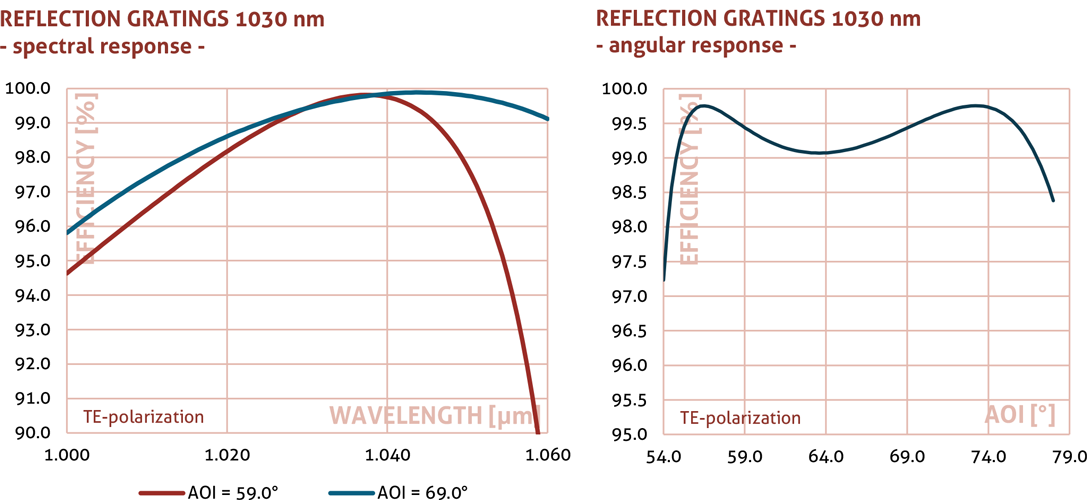

In terms of optical performance, the 1030 nm transmission grating delivers outstanding diffraction efficiency, exceeding 95% within the target wavelength range, significantly reducing energy loss in the system. It features high-precision wavelength tuning with an accuracy of ±0.1 nm, meeting the stringent spectral requirements of ultrafast pulse compression, spectral beam combining, and other demanding applications. Furthermore, its excellent optical uniformity and low wavefront distortion guarantee stable beam quality output, ensuring reliable performance in precision applications.

To meet diverse application requirements, the 1030 nm transmission grating is available in multiple specifications, including different line densities (600–1800 lines/mm), a variety of sizes, and substrate options such as fused silica. Each grating undergoes strict manufacturing control and comprehensive quality testing to ensure stable performance and long service life.

Notes: For best performance, store and operate the grating at 25 °C and 40%–60% relative humidity. If the grating surface becomes contaminated, gently clean it with >99% alcohol and lint-free lens tissue. Avoid rough fabrics, water, or abrasive cleaners to prevent damage to the coating.

Product evaluation

%High praise

There are comments